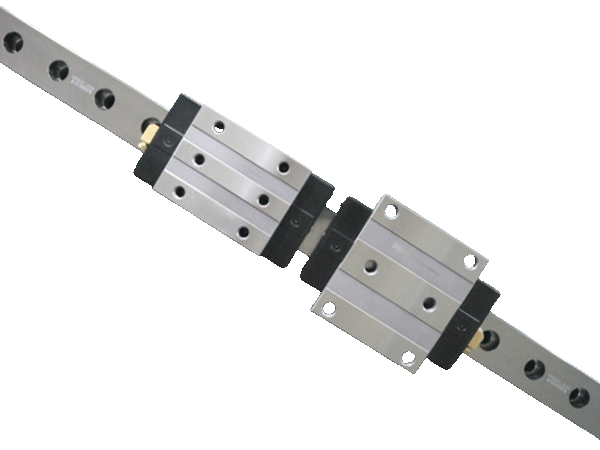

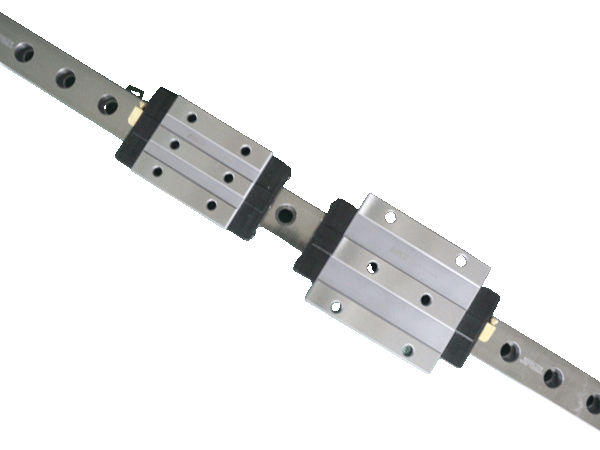

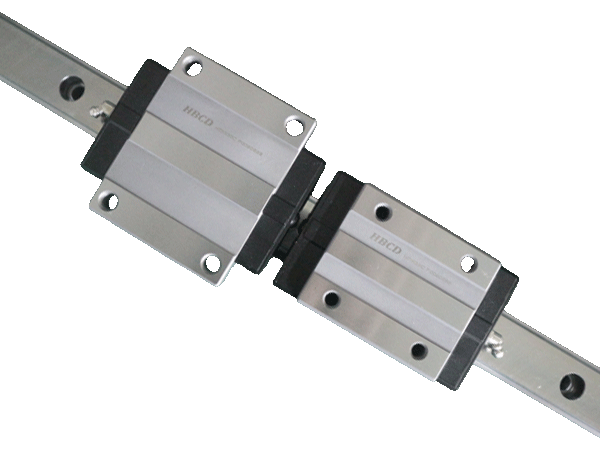

Hanbang Transmission RD Series

Keywords:

Hanbang Transmission RD Series

Classification:

Product Introduction

High Positioning Accuracy

When using linear guide rail as linear guide, since the friction mode of linear guide rail is rolling friction, not only the friction coefficient is reduced to 1/50 of sliding guide, but also the difference between dynamic friction force and static friction force becomes very small. Therefore, when the bed is running, there will be no slippage, and the positioning accuracy of μm level can be achieved. The low wear of

can maintain the precision of

traditional sliding guidance for a long time. Inevitably, the platform motion precision will be poor due to the reverse flow of oil film, and the contact surface of the running track will be worn due to insufficient lubrication during motion, which will seriously affect the precision. The wear of rolling guidance is very small, so the machine can maintain accuracy for a long time.

is suitable for high-speed movement and greatly reduces the driving horsepower required for the machine

Because the friction force is very small when the linear guide rail moves, only a small power is required to make the bed run, especially when the working mode of the bed is regular round-trip operation, the power loss of the machine can be significantly reduced. And because the heat generated by its friction is small, it can be applied to high-speed operation.

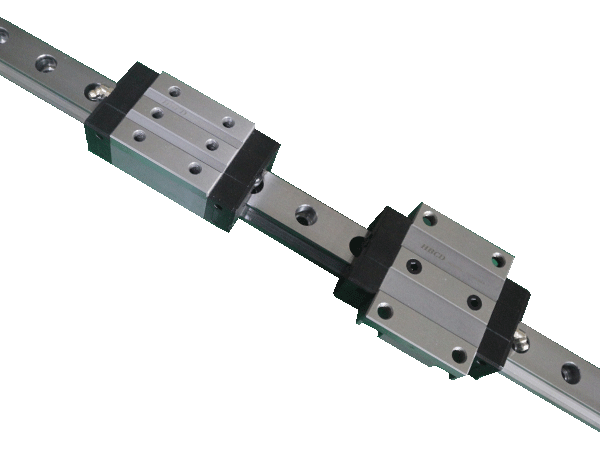

can bear the load in the up, down, left and right directions at the same time

due to the special bundle structure design of the linear guide rail, it can bear the load in the up, down, left and right directions at the same time, unlike the sliding guide, which can bear lighter lateral load in the direction parallel to the contact surface, which is easy to cause poor operation accuracy of the machine.

Easy to assemble and interchangeable

Only milling or grinding the bed when assembled. Install the assembly surface of the guide rail, and fix the guide rail and slider on the machine table with specific torque according to the recommended steps, which can reproduce the high precision during processing. In the traditional sliding guidance, the running track must be shoveled, which is time-consuming and time-consuming, and once the accuracy of the machine is poor, it must be shoveled again. The linear guide rail is interchangeable, and the slider or the guide rail or even the linear guide rail group can be replaced respectively, and the machine can regain the high precision guidance.

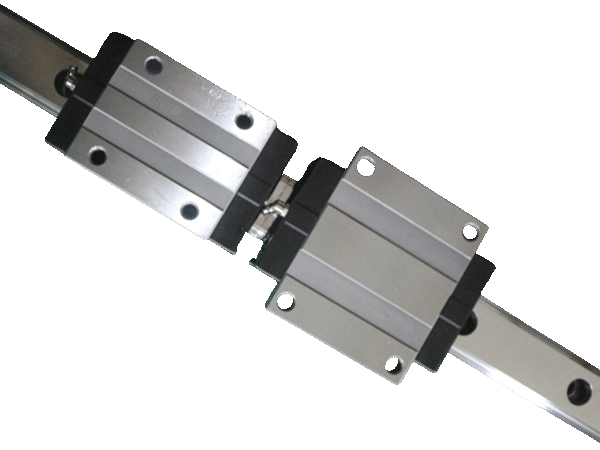

Lubrication Structure Simple

If the sliding guide is not lubricated enough, it will cause direct friction loss of the metal on the contact surface. However, it is not easy to lubricate the sliding guide sufficiently, and it is necessary to drill oil at the appropriate position of the bed. The linear guide rail has been installed with a grease nozzle on the slider, which can be directly injected with grease by a grease gun, or can be replaced with a special oil pipe joint to connect the oil supply pipe for lubrication by an automatic oil supply machine.

Product Message

Related Products

Weipeng Technology

Company address: Industrial Park, High-speed Railway New District, Liaocheng City, Shandong Province