20

2023-03

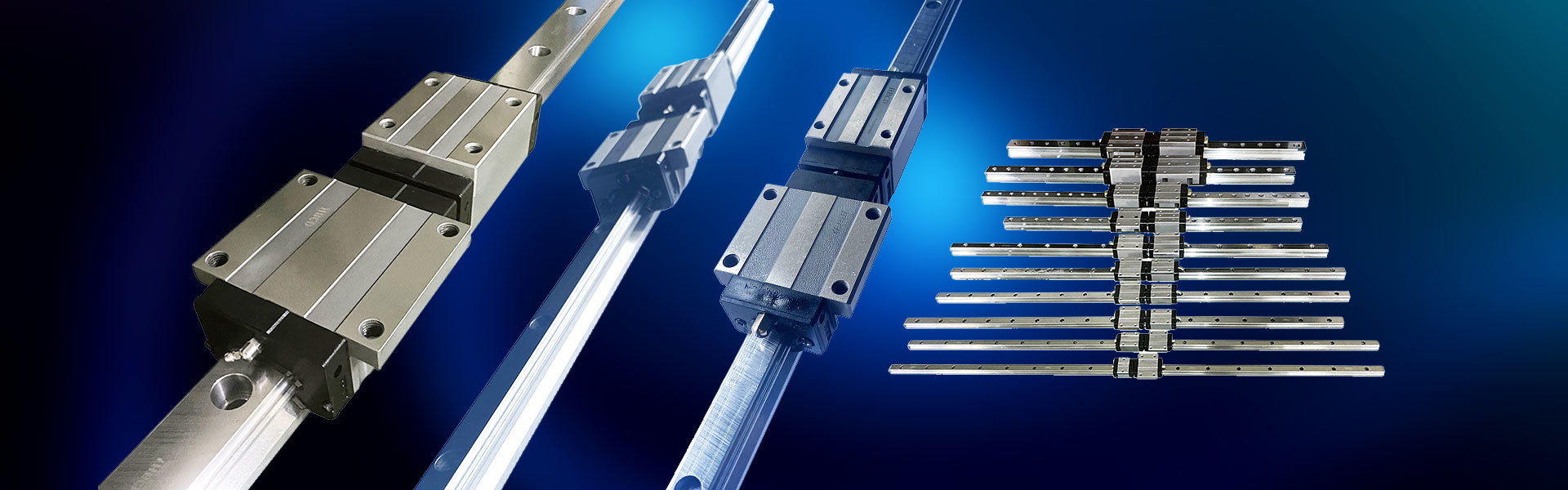

How to reduce storage space when storing linear guide

How to reduce storage space when storing linear guide! All directions have high rigidity. Four-row arc grooves are used to match the contact angle of 45 degrees such as four-row steel balls, so that the steel balls can achieve the ideal two-point contact structure and can bear the load from the up and down and left and right directions. When necessary, preload can be applied to improve rigidity.

2023-03-20

23

2023-02

Effective way to improve the accuracy of linear guide equipment!

Centrifugal molding is an important process to reduce the material consumption of linear guide equipment and mold cost. The development of multi-station fully automated centrifugal linear guide equipment is a hot spot in the market. Degreant bottle-making linear guide equipment is also developing towards high precision and high output. One of the key technologies to improve the surface quality of linear guide equipment is flame polishing of the surface of products, how to improve the accuracy and automation of polishing linear guide equipment to adapt to mass production.

2023-02-23

28

2023-01

Linear guide to prevent rust by increasing the frequency of use and efficiency

Let the shutdown time greatly shortened, so that the linear guide rail time in the state of travel and work, by improving the frequency of use and efficiency to prevent rust. If you can strictly control the amount of linear guide that would be good, as long as the amount of pure within the specified range, the use of the cycle is generally relatively long. At the same time, if you can reduce the noise on the linear guide interference that is perfect. When working in a high-speed environment, try to reduce the temperature rise speed of the motor, and do not let the motor throw oil. If the power consumption can be reduced, it is better to give the motor protection.

2023-01-28

Weipeng Technology

Company address: Industrial Park, High-speed Railway New District, Liaocheng City, Shandong Province