How to reduce storage space when storing linear guide

Published:

2023-03-20

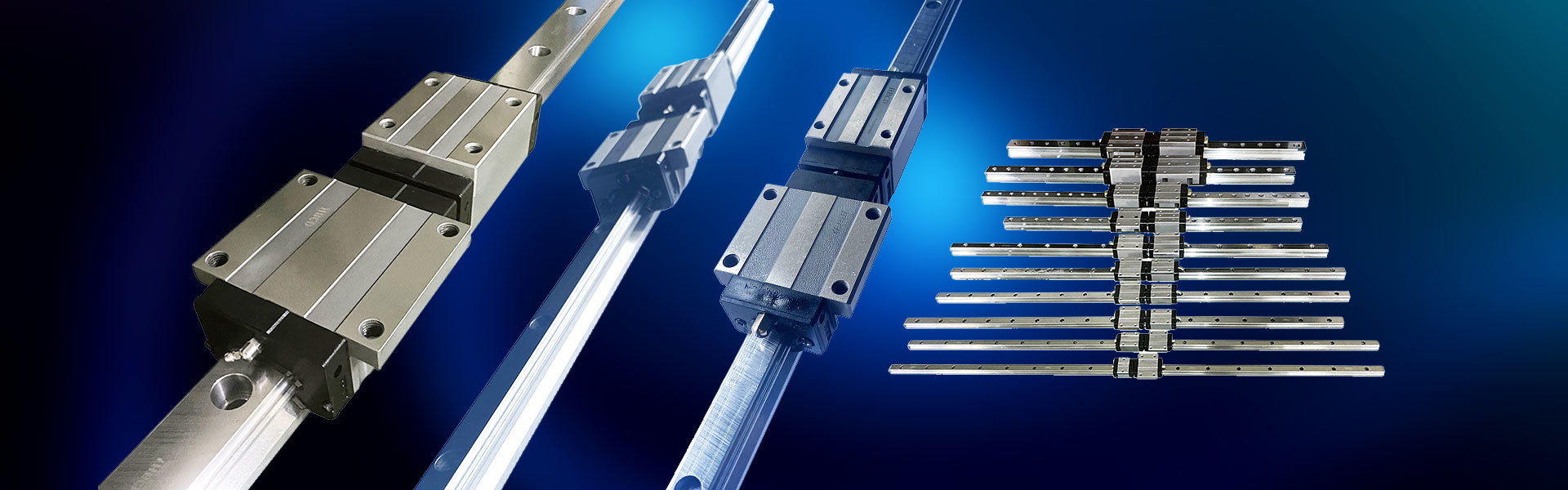

How to reduce storage space when storing linear guide! All directions have high rigidity. Four-row arc grooves are used to match the contact angle of 45 degrees such as four-row steel balls, so that the steel balls can achieve the ideal two-point contact structure and can bear the load from the up and down and left and right directions. When necessary, preload can be applied to improve rigidity.

linear guide how to reduce storage space when stored! All directions have high rigidity. Four-row arc grooves are used to match the contact angle of 45 degrees such as four-row steel balls, so that the steel balls can achieve the ideal two-point contact structure and can bear the load from the up and down and left and right directions. When necessary, preload can be applied to improve rigidity.

linear guide rail can be understood as a rolling guide, which is an infinite rolling cycle between the sliding block and the guide rail by steel balls, so that the load platform can easily move linearly with high precision along the guide rail, and the friction coefficient is reduced to one of the five conventional sliding guides, which can easily achieve high positioning accuracy. The design of the final unit between the

slider and the guide rail enables the linear guide rail to bear the load in all directions such as up, down, left and right at the same time. Its reflux system and simplified structural design enable the linear guide rail to move more smoothly and with low noise. The design of the guide rail system strives to have a large contact area between the fixed element and the moving element, which not only improves the bearing capacity of the system, but also the system can withstand the impact force generated by intermittent cutting or gravity cutting, spreading the force widely and expanding the bearing area. In order to achieve this, the groove shape of the guide rail system has a variety of, there are two representative, one is called the pointed arch, the shape is the extension of the semicircle, the contact point is the vertex;

The other is a circular arc, which can also play the same role. No matter what kind of structure, the purpose is only one, and strive to make more rolling steel ball radius contact with the guide rail (fixed element). The factors that determine the performance characteristics of the system are how the rolling elements contact the guide rail, which is the key to the problem.

. The automatic centering capability comes from the combination of arc grooves. During installation, even if the installation surface is somewhat deviated, it can be absorbed by the inside of the line rail slider by the elastic deformation of steel balls and the transfer of contact points, thus generating the automatic centering capability and obtaining high-precision and stable smooth movement.

2. Interchangeability Due to strict control of production and manufacturing precision, the size of linear guide rail can be maintained within a certain level, and the slider is designed with a retainer to prevent steel balls from falling off. Therefore, some series of precision are interchangeable. Customers can order guide rails or sliders as needed, or store guide rails and sliders separately to reduce storage space.

Key words:

Previous article

Related News

JME Tianjin International Machine Tool Show

2023-09-07

DME Dongguan International Machine Tool Show

2023-11-09

SME Suzhou International Machine Tool Show

2024-03-20

The Balancing Function of Linear Guide

2023-07-18

What are the advantages of the rail slider?

2023-07-12

How to adjust the clearance of linear guide?

2023-06-02

Weipeng Technology

Company address: Industrial Park, High-speed Railway New District, Liaocheng City, Shandong Province