What is the impact of water separation on the linear guide?

Published:

2023-07-10

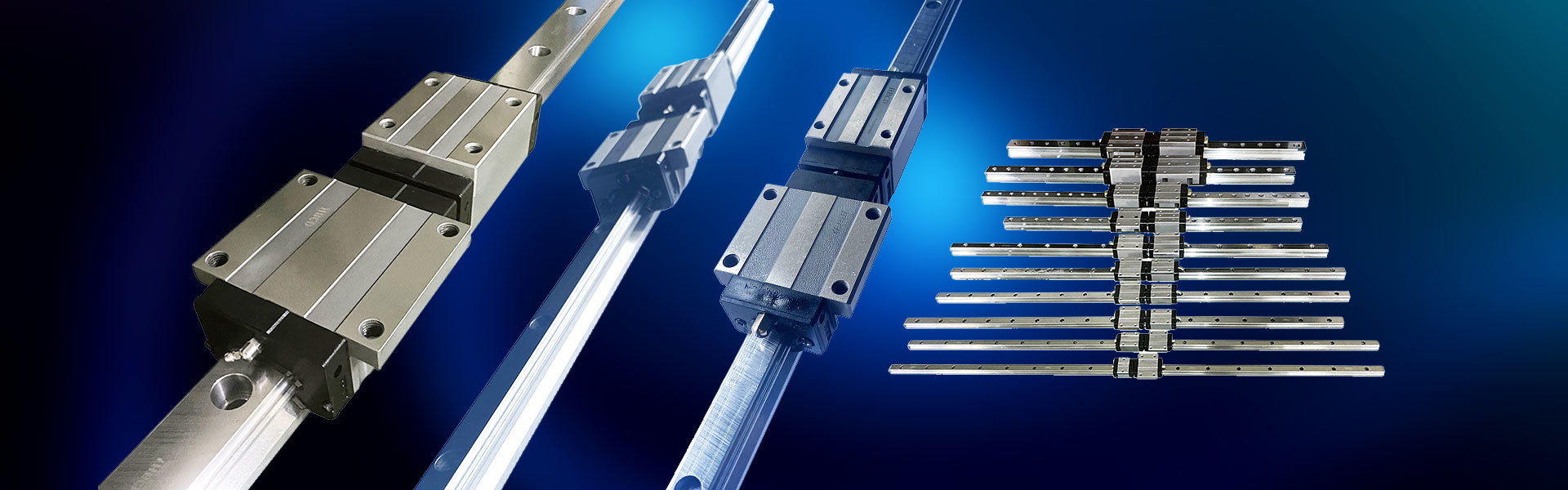

Linear guide in the production and processing will inevitably be splashed by water, if the rail oil in the water performance is not very good, then it will be directly decomposed by water, oil will drip into the cutting fluid, resulting in cutting fluid is seriously polluted, so the linear guide in the water performance is very important. In addition, the working time is too long, the steel ball begins to wear, and the preload acting on the steel ball begins to weaken, resulting in the reduction of the motion accuracy of the working parts of the machine tool. If you want to maintain the initial accuracy, you must replace the linear guide bracket, or even replace the guide rail.

linear guide will inevitably be splashed by water in the production and processing. If the guide rail oil is not very good in the water splitting performance, it will be directly decomposed by water, and the oil will drip into the cutting fluid, resulting in serious pollution of the cutting fluid. Therefore, the linear guide rail is very important in the water splitting performance.

In addition, the working time is too long, the steel ball begins to wear, and the preload acting on the steel ball begins to weaken, resulting in a decrease in the movement accuracy of the working parts of the machine tool. If you want to maintain the initial accuracy, you must replace the linear guide bracket, or even replace the guide rail.

If the rail system has a pre-load effect and the system accuracy has been lost, the effective method is to replace the rolling elements. It can be seen that when the linear guide is in use, a little carelessness will cause damage to the parts. In the production operation, we must adopt a more cautious production attitude to avoid the damage caused by incorrect use of the linear guide.

for the use of the environment linear guide also has a relatively high use requirements, in our production environment, there are not only visible dust, but also some invisible dust, once the dust falls into the linear guide, there will be some adverse reactions, such as improving the wear degree of the guide rail, so that the mechanical vibration force increased, and then there is the noise and so on, this will then lead to other problems of use.

For the installation of linear guide rails, it is also necessary to be careful. During installation, there should be no strong stamping, nor should heavy objects be used to install and knock the guide rails. In case of improper installation, technical behavior should be adopted for installation. Avoid directly using both hands to take such accessories, and the correct way is to clean your hands before use, remove stains and sweat, and then apply some mineral grease on the linear guide rail, and then carry out other operations. Especially in the humid summer, we must do a good job of moistureproof treatment.

Key words:

Previous article

Related News

JME Tianjin International Machine Tool Show

2023-09-07

DME Dongguan International Machine Tool Show

2023-11-09

SME Suzhou International Machine Tool Show

2024-03-20

The Balancing Function of Linear Guide

2023-07-18

What are the advantages of the rail slider?

2023-07-12

How to adjust the clearance of linear guide?

2023-06-02

Weipeng Technology

Company address: Industrial Park, High-speed Railway New District, Liaocheng City, Shandong Province