The Balancing Function of Linear Guide

Published:

2023-07-18

To establish good service quality of linear slide rail, the initial condition of success or failure is to select the correct specifications and models, but the final key factor affecting the service quality is the installation quality of linear slide rail. Even if the correct model of linear slide rail is selected, it is easy to greatly affect the product life and the performance of the organization operation due to poor installation quality. Good installation quality is based on complying with the installation design principles and installation steps of linear slide rail, the following are the design matters and installation steps that should be paid attention to when installing the linear slide.

To establish good service quality of linear slide rail, the initial condition of success or failure is to correctly select specifications and models, but the final key factor affecting the service quality lies in the installation quality of linear slide rail. Even if the correct model of linear slide rail is selected, it is easy to greatly affect the product life and the performance of mechanism operation due to poor installation quality, the good installation quality is based on the compliance with the linear slide installation design principles and installation steps. The following are the design matters and installation steps that should be paid attention to when installing the linear slide.

Tighten the positioning screws of the slide rail in sequence from the center to both sides to make the rail slightly fit the vertical mounting surface. The sequence is from the central position to the two ends of the tightening can be more stable accuracy. After the vertical reference plane is slightly tightened, strengthen the locking force of the lateral reference plane, so that the main rail can really fit the lateral reference plane. Linear bearings are mainly used in automated machinery, such as machine tools imported from Germany, paper bowl machines, laser welding machines, etc., of course, linear bearings and linear axes are used.

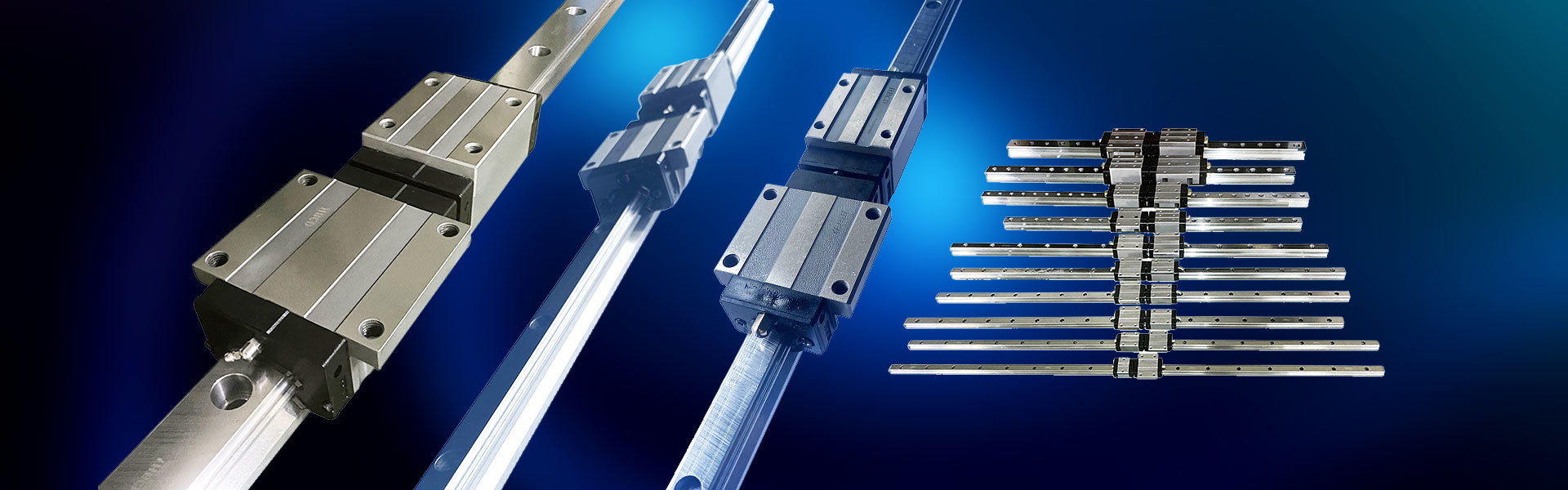

Like a linear guide rail is mainly used in the mechanical structure with high precision requirements. No intermediate medium is used between the moving element and the fixed element of the linear guide rail, but rolling steel balls are used. Because the rolling steel ball is suitable for high-speed movement, the friction coefficient is small, and the sensitivity is high, it can meet the working requirements of moving parts, such as the tool holder of the machine tool, the carriage, etc. If the force acting on the steel ball is too large, the steel ball is subjected to the preload for too long, resulting in an increase in the movement resistance of the bracket. There is a balance problem here; in order to improve the sensitivity of the system and reduce the movement resistance, the preload should be reduced accordingly, and in order to improve the movement accuracy and the maintenance of accuracy, it is necessary to have enough pre-added negative numbers, which are contradictory two aspects. The design of the rail system strives to have the largest contact area between the fixed element and the moving element, which not only improves the bearing capacity of the system, but also the system can withstand the impact force generated by intermittent cutting or gravity cutting, spreading the force widely and expanding the bearing area. The development of

synchronous belt wheel manufacturing process is largely reflected in the accuracy level and production efficiency. Since the 1970 s, the manufacturing accuracy of various synchronous pulleys has generally increased by one level or so. Some even 2~3. Generally, the accuracy of low-speed synchronous belt wheels has been increased from 8 to 9 levels in the past to 7 to 8 levels. Machine tool synchronous belt wheel from 6~8 level to 4~6 level. The synchronous belt wheel of rolling mill is improved from grade 7~8 to grade 5~6. For small and medium-sized synchronous pulleys with small modulus, due to the development of high-performance gear hobbing machines and the improvement of tool materials, the gear hobbing efficiency has been significantly improved. With a multi-head hob, the achievable cutting speed is 90 m/s under high feed and conditions. If a superhard hob is used to process a quenched and tempered steel synchronous pulley with a modulus of about 3, the excessive cutting can reach 200 m/s. To improve the gear cutting efficiency, it is limited by the reciprocating motion mechanism of the gear cutting machine. Recently in the development of the use of tool unloading, the use of hydrostatic bearings, enhanced tool holder and column rigidity and other new structures, the efficiency has been significantly improved. The number of strokes of the new gear shaper can reach 2000 times/min. The development of low-noise synchronous belt wheel device is some of the characteristics of synchronous belt wheel design. In order to achieve the miniaturization of the synchronous belt wheel device, the bearing thrust of the existing involute synchronous belt wheel can be improved.

Key words:

Previous article

Related News

JME Tianjin International Machine Tool Show

2023-09-07

DME Dongguan International Machine Tool Show

2023-11-09

SME Suzhou International Machine Tool Show

2024-03-20

The Balancing Function of Linear Guide

2023-07-18

What are the advantages of the rail slider?

2023-07-12

How to adjust the clearance of linear guide?

2023-06-02

Weipeng Technology

Company address: Industrial Park, High-speed Railway New District, Liaocheng City, Shandong Province