21

2023-07

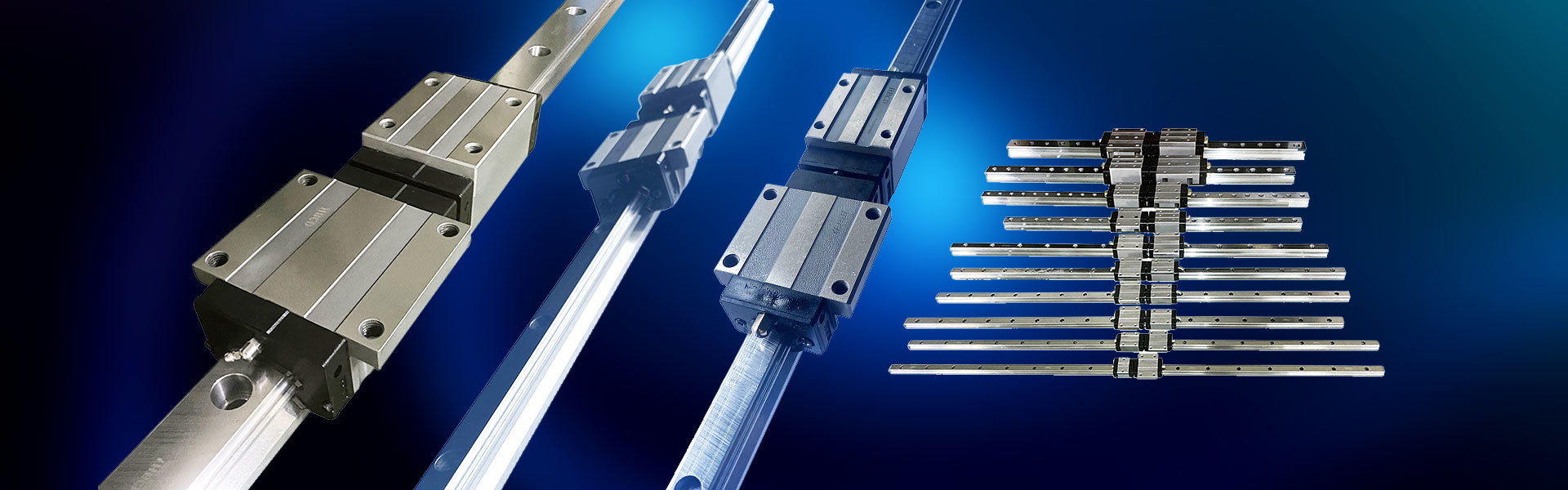

What are the reasons for the linear guide being strongly respected?

We all know that linear guides are used on machine tools, and the purpose of machine tools is to manufacture and produce. Therefore, this will involve the issue of a delivery cycle. In this era of every second, the shorter the delivery cycle, the better the product, and the more natural the competitiveness. This is also one of the reasons why linear guides are strongly recommended for use. And the linear guide is really respected by the use of more than that, mainly because of the following points.

2023-07-21

18

2023-07

The Balancing Function of Linear Guide

To establish good service quality of linear slide rail, the initial condition of success or failure is to select the correct specifications and models, but the final key factor affecting the service quality is the installation quality of linear slide rail. Even if the correct model of linear slide rail is selected, it is easy to greatly affect the product life and the performance of the organization operation due to poor installation quality. Good installation quality is based on complying with the installation design principles and installation steps of linear slide rail, the following are the design matters and installation steps that should be paid attention to when installing the linear slide.

2023-07-18

12

2023-07

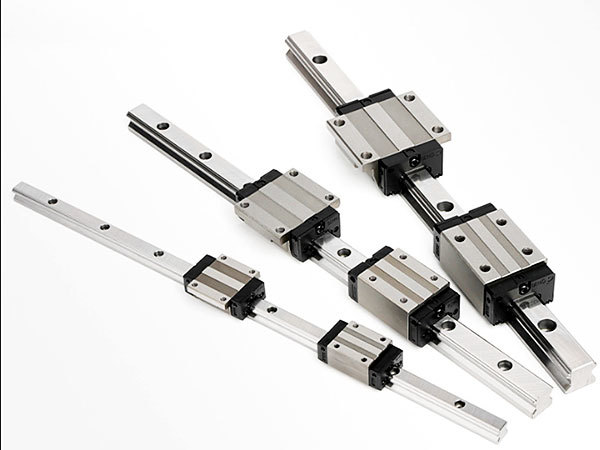

What are the advantages of the rail slider?

Guide slider is a common mechanical transmission element, mainly composed of guide rail and slider, commonly used in industrial automation equipment and CNC machine tools and other fields. The rail slider has the advantages of high precision, strong load capacity, stable movement, space saving, high rigidity, easy maintenance, etc., which can meet the needs of industrial automation equipment and CNC machine tools, and improve production efficiency and product quality.

2023-07-12

10

2023-07

What is the impact of water separation on the linear guide?

Linear guide in the production and processing will inevitably be splashed by water, if the rail oil in the water performance is not very good, then it will be directly decomposed by water, oil will drip into the cutting fluid, resulting in cutting fluid is seriously polluted, so the linear guide in the water performance is very important. In addition, the working time is too long, the steel ball begins to wear, and the preload acting on the steel ball begins to weaken, resulting in the reduction of the motion accuracy of the working parts of the machine tool. If you want to maintain the initial accuracy, you must replace the linear guide bracket, or even replace the guide rail.

2023-07-10

02

2023-06

Linear guide can be customized according to customer requirements

In order to ensure that the linear guide is in normal working condition for a long time, a proper gap should be maintained between the sliding surfaces of the linear guide. If the gap is too small, the friction will increase, and if the gap is too large, the guiding accuracy will be reduced. To this end in the daily processing is generally used to insert and pressure plate to adjust the linear guide clearance. In order to ensure the accuracy between the linear guide and the use of the degree of loss, greatly improving the efficiency of production.

2023-06-02

02

2023-06

How to adjust the clearance of linear guide?

In order to ensure that the linear guide is in normal working condition for a long time, a proper gap should be maintained between the sliding surfaces of the linear guide. If the gap is too small, the friction will increase, and if the gap is too large, the guiding accuracy will be reduced. To this end in the daily processing is generally used to insert and pressure plate to adjust the linear guide clearance. In order to ensure the accuracy between the linear guide and the use of the degree of loss, greatly improving the efficiency of production.

2023-06-02

11

2023-05

Discussion on the Market Requirements for Miniature Linear Guide

Micro linear guide as a common functional component in the machinery industry, the use of high frequency. Therefore, with the development of the micro linear guide industry, there are great requirements for the wear resistance and accuracy of the micro guide. At present, there are different types of products in the guide rail industry. Which linear guide rail can be purchased according to the application requirements of the actual guide rail.

2023-05-11

20

2023-03

How to reduce storage space when storing linear guide

How to reduce storage space when storing linear guide! All directions have high rigidity. Four-row arc grooves are used to match the contact angle of 45 degrees such as four-row steel balls, so that the steel balls can achieve the ideal two-point contact structure and can bear the load from the up and down and left and right directions. When necessary, preload can be applied to improve rigidity.

2023-03-20

23

2023-02

Effective way to improve the accuracy of linear guide equipment!

Centrifugal molding is an important process to reduce the material consumption of linear guide equipment and mold cost. The development of multi-station fully automated centrifugal linear guide equipment is a hot spot in the market. Degreant bottle-making linear guide equipment is also developing towards high precision and high output. One of the key technologies to improve the surface quality of linear guide equipment is flame polishing of the surface of products, how to improve the accuracy and automation of polishing linear guide equipment to adapt to mass production.

2023-02-23

28

2023-01

Linear guide to prevent rust by increasing the frequency of use and efficiency

Let the shutdown time greatly shortened, so that the linear guide rail time in the state of travel and work, by improving the frequency of use and efficiency to prevent rust. If you can strictly control the amount of linear guide that would be good, as long as the amount of pure within the specified range, the use of the cycle is generally relatively long. At the same time, if you can reduce the noise on the linear guide interference that is perfect. When working in a high-speed environment, try to reduce the temperature rise speed of the motor, and do not let the motor throw oil. If the power consumption can be reduced, it is better to give the motor protection.

2023-01-28

Weipeng Technology

Company address: Industrial Park, High-speed Railway New District, Liaocheng City, Shandong Province